One of our AIDA HD100A's stopped powering on. As it turned out, one of the pins (DC power+) of the "I/O" connector had broken from the receptacle on the camera.

What has likely happened, is that the connector bent the pin while it was being turned it to find the right mating position. These are Hirose HR10A connectors (or at least, they look very much like them), of which Hirose writes they have a "Five-key system that permits only one way of coupling so that you can find right position to connect even when blind mating".

In theory, it would not be possible to bend a pin, because of the "five-key" system that would never allow the connector to sink deep enough into the receptacle when not in the right position.

A good question. Because we also had another cable that was failing to bring up the OSD through the joystick on the breakout-cable, I disassembled two cables, to find that a number of wires had already snapped. That is pretty amazing, because these camera's don't get much use (the oldest has been used during 10 livestream shows (not particularly rock concerts, mind you) now, but the other HD100A's not even 4).

Probably yes. I've ordered an original Hirose HR10A panel-mount receptacle and connector from a reputable seller. These should be the same connectors that are on the AIDA HD100A (12-pin panel-mount male dip soldering type) and breakout cable (12-pin solder type female connector). Inspecting these original connectors and carefully reading the Hirose documentation, it quickly becomes clear that something is wrong here. These connectors are likely not manufactured by Hirose. But worse: the cables have not even been manufactured by Hirose specifications.

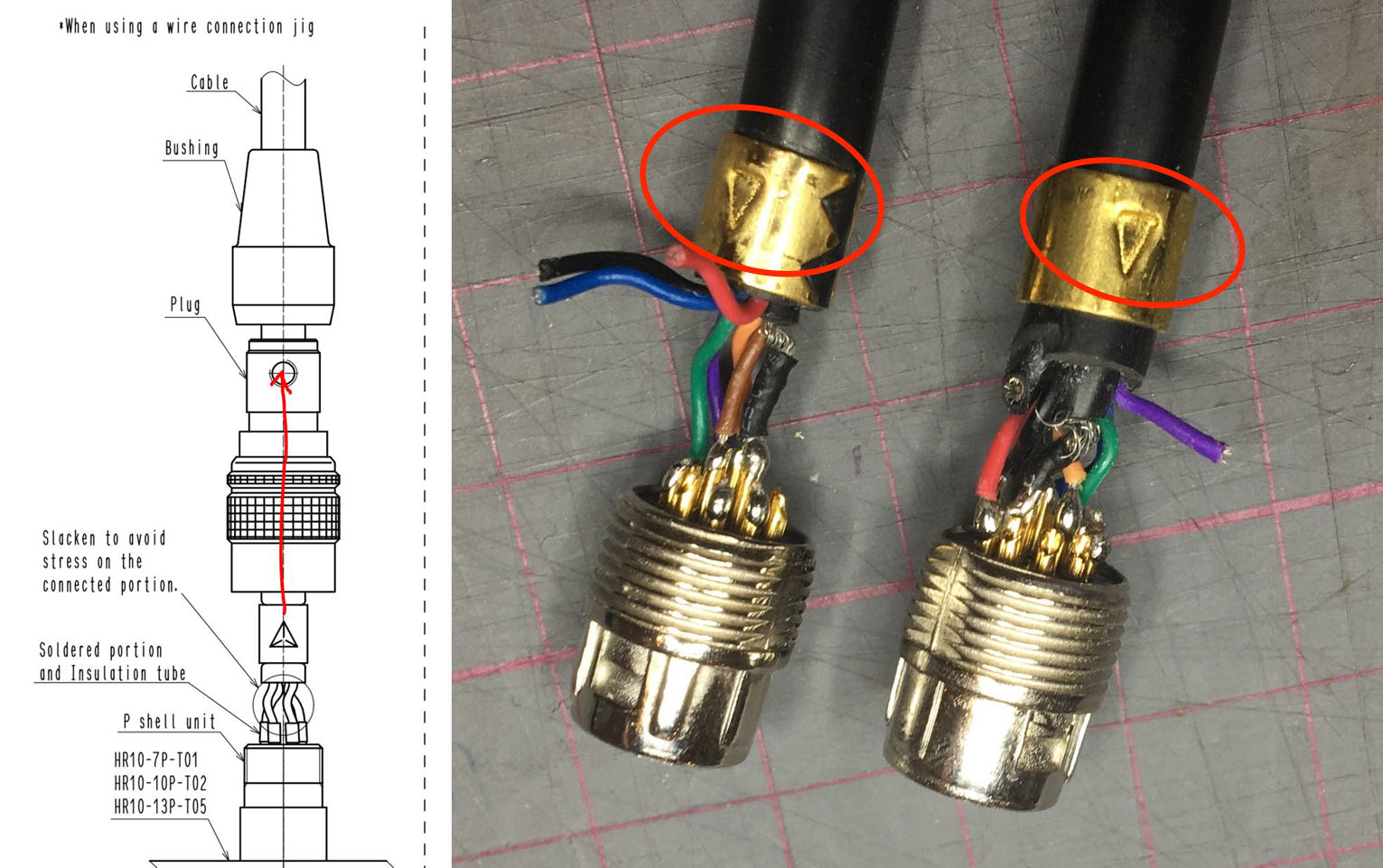

In the above picture it clearly shows that the clamp ring with "boss" (concave indent) is facing the wrong way on the AIDA HD100A cables (right). I've sent this matter to Hirose, and they have confirmed that the clamp should face the other way, as in their spec (on the left, image provided by Hirose technical support).

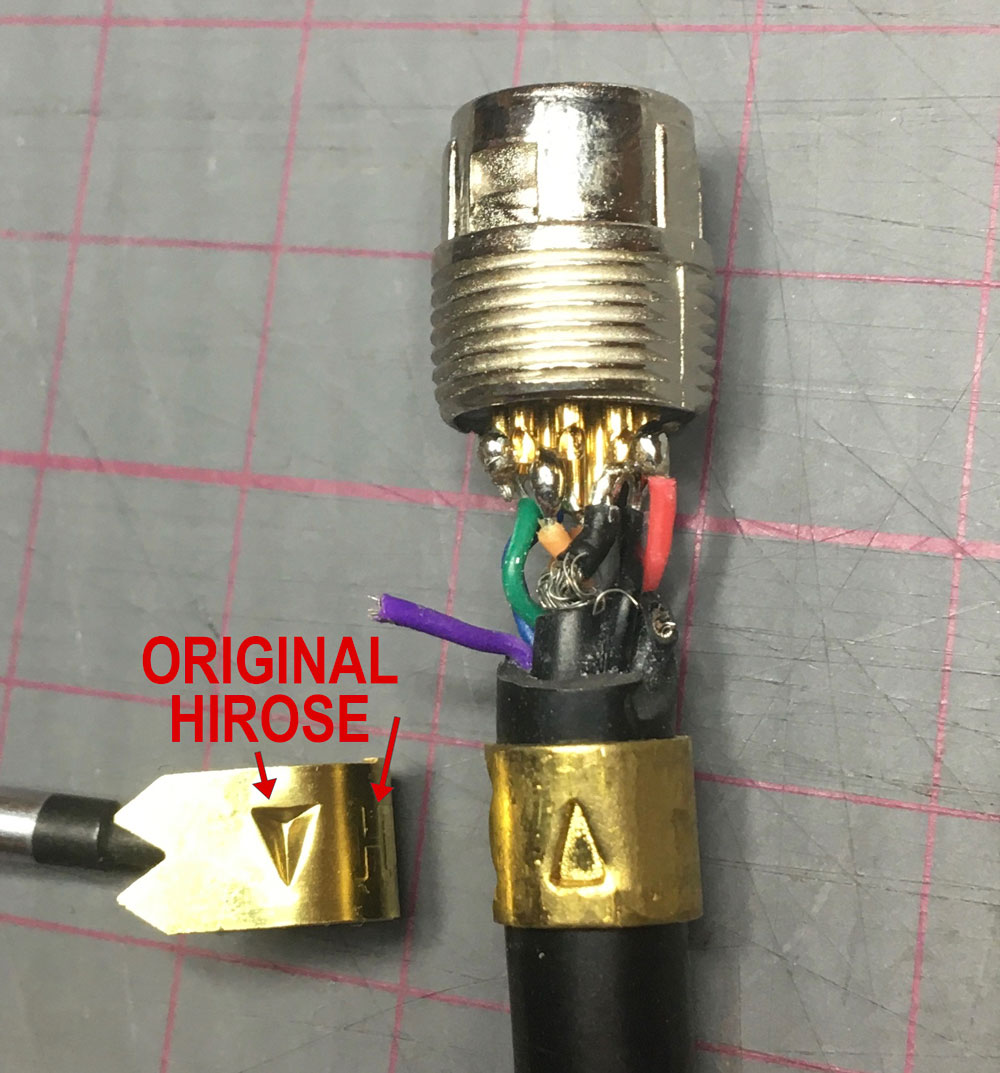

In the image below you can also clearly see there's a difference between the boss on an original Hirose cable clamp, and the clamps on the AIDA cables. The Hirose clamp has their logo stamped into it, the indent is much deeper and has a different shape.

I was skeptical of a strain relief that relies on a tiny set screw, but I'm told by an electronics expert with many years of experience with (original) Hirose HR10 connectors, that they are extremely reliable. Hirose specs them at 1000 matings, but I was told this is just to cover liability issues, and the connectors can withstand way more matings in practice.

But it's clear with this design that when the strain relief fails, or the two parts of the connector shell unscrew from eachother, Bad Things™ happen quickly. It's hard to tell if this is indeed what happened, and if this may have caused the pin on the camera to bend and break. But it's not unlikely.

After showing some of these pictures to the forementioned electronics expert, he noticed that there was way too much solder applied on the wires to the connector, and that heat shrink tubing should be applied for connectors designed for "field use". He also mentioned that it is advisable to use Locktite or a similar product to prevent the two parts of the connector shell from unscrewing. Hirose techinical support sent me a document in which they recommend to use Locktite for the set screw as well. The AIDA cables don't show any sign of this.

In the above picture you can clearly see that the AIDA connector differs on many points from an original Hirose HR10A.

The scratches on the black plastic insert are telling for what's happening when turning the cable to find the right mating position. That should not happen, but probably does because of the inaccuracies in the connector body.

Again, a good question. We are quite happy with the HD100A's, mostly because they're extremely small and lightweight. Finetuning them to the max (using our custom-written software over an RS-485 connection to the camera's) we eventually get a pretty decent image out of them. That's also because we control the entire lighting setup in our shows, the HD100A's (and especially the low quality lenses that are available for them) are not well-suited for more challenging lighting conditions.

And up until recently, I also thought that the connectors (which feel and look sturdy at first sight) were not something we'd have to worry about. But that now turns out to be their greatest weakness. We can't rely on these cables for live productions, because they're just not manufactured to spec. Not only can they fail after light use, they can actually damage our camera's. These "budget-friendly" camera's suddenly become expensive when this happens. We could replace the female connectors on the cables with original Hirose's (even use HR10's instead of HR10A's), but we'd likely be voiding AIDA's warranty in doing so. Original Hirose HR10's cost over 10% of what an entire HD100A costs, so the "budget-friendliness" would be reduced significantly by doing this. We could also just skip the HD100A's and get more reliable camera's. These would probably be bigger, and we'd throw away all the time we've invested in these camera's (including writing custom software to control them over RS-485).

So yeah, time to contemplate...

Back in november 2020, for our first ever livestream we ordered a HD100A. We couldn't use it for the show, because the audio input didn't work. There was no time left for the show to have it swapped, so we took a DSLR with high-end lens, which was total overkill for a livestream in Full-HD quality.

I now wonder if it wasn't the camera itself, but the cable that was already faulty out of the box? Are more cables failing because they're poorly constructed?

The broken pin could have been replaced relatively easy when the panel mount connector would have been an original Hirose. This pin (pin 9) has quite some space on the PCB to de/resolder, and the Hirose pins can be removed and inserted again. But the pins (knock-off?) connector on the AIDA HD-100A don't allow for removal/replacement. They seem to be cast in the plastic inner casing. A typical case of "cheaper option" with "expensive outcome"?